Edible Oil Refining Process: Water Degumming

Product Description

Degumming process in oil refining plant is to remove gum impurities in crude oil by physical or chemical methods, and it is the first stage in oil refining / purification process. After screw pressing and solvent extracting from oilseeds, the crude oil mainly contains triglycerides and few non-triglyceride. The non-triglyceride composition including phospholipids, proteins, phlegmatic and sugar would react with triglycerides to form colloid, which is known as gum impurities.

The gum impurities not only affect the stability of the oil but also affect the process effect of oil refining and deep processing. For instance, non-degummed oil is easy to form an emulsified oil in the alkaline refining process, thus increasing the difficulty of operation, oil refining loss, and auxiliary material consumption; in the decolorization process, non-degummed oil will increase the consumption of adsorbent and reduce discoloring effectiveness. Therefore, gum removing is necessary as the first step in oil refinery process before oil deacidification, oil decolorization, and oil deodorization.

The specific methods of degumming include hydrated degumming(water degumming), acid refining degumming, alkali refining method, adsorption method, electropolymerization and thermal polymerization method. In edible oil refining process, the most commonly used method is hydrated degumming, which can extract the hydratable phospholipids and some non-hydrate phospholipids, while the remaining non-hydrate phospholipids need to be removed by acid refining degumming.

1. Working principle of hydrated degumming (water degumming)

The crude oil from the solvent extraction process contains water soluble components, primarily comprised of phospholipids, which need to be removed from the oil to enable minimum precipitation and settling during oil transport and long term storage. The gum impurities such as phospholipids have the characteristic of hydrophilic. First of all, you can stir and add a certain amount of hot water or electrolyte aqueous solution like salt & phosphoric acid to the hot crude oil. After a certain reaction period, the gum impurities would be condensated, subsided and removed from the oil. In the hydrated degumming process, the impurities are mainly phospholipid, as well as a few protein, glyceryl diglyceride, and mucilage. What’s more, the extracted gums could be processed into lecithin for food, animal feed or for technical uses.

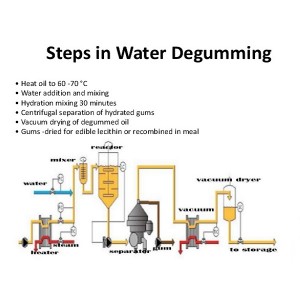

2. The process of hydrated degumming (water degumming)

The water degumming process involves adding water to the crude oil, hydrating the water soluble components, and then removing the majority of them via centrifugal separation. The light phase after centrifugal separation is the crude degummed oil, and the heavy phase after centrifugal separation is a combination of water, water soluble components and entrained oil, collectively referred to as “gums”. The crude degummed oil is dried and cooled before being sent to storage. The gums are pumped back onto the meal.

In oil refining plant, the hydrated degumming machine can be operated together with oil deacidification machine, decolorization machine, and deodorizing machine, and these machines are the composition of the oil purifying production line. The purifying line is classified into intermittent type, semi-continuous type, and fully continuous type. The customer could choose the type according to their required production capacity: the factory with a production capacity of 1-10t per day is suitable for using intermittent type equipment, 20-50t per day factory is suitable for using semi-continuous type equipment, producing more than 50t per day is suitable for using fully continuous type equipment. The most commonly used type is the intermittent hydrated degumming production line.

Technical Parameter

The main factors of Hydrated degumming (water degumming)

3.1 Volume of added water

(1) Effect of added water on flocculation: A proper amount of water can form a stable multi-layer liposome structure. Insufficient water will lead to incomplete hydration and bad colloidal flocculation; Excessive water tends to form water-oil emulsification, which is difficult to separate impurities from the oil.

(2) The relationship between added water content (W) and glum content (G) in different operating temperature:

|

low temperature hydration(20~30℃) |

W=(0.5~1)G |

|

medium temperature hydration(60~65℃) |

W=(2~3)G |

|

high temperature hydration(85~95℃) |

W=(3~3.5)G |

(3) Sample test: Appropriate amount of added water can be determined through a sample test.

3.2 Operating temperature

The operation temperature is generally corresponding to the critical temperature (for better flocculation, operation temperature can be slightly higher than the critical temperature). And the operation temperature will affect the amount of added water when the temperature is high, the amount of water is large, otherwise, it is small.

3.3 Intensity of hydration mixing and reaction time

(1) Inhomogeneous hydration: Gum flocculation is a heterogeneous reaction at the interaction interface. In order to form a stable oil-water emulsion state, mechanical mixing the mixture can make the droplets fully dispersed, mechanical mixing needs to be intensified especially when the amount of added water is large and the temperature is low.

(2) Intensityof hydration mixing: When mixing oil with water, the stirring speed is 60 r/min. At the period of flocculation generating, the stirring speed is 30 r/min. The reaction time of hydration mixing is around 30 minutes.

3.4 Electrolytes

(1) Varieties of electrolytes: Salt, alum, sodium silicate, phosphoric acid, citric acid and dilute sodium hydroxide solution.

(2) The main function of electrolyte:

a. Electrolytes can neutralize some electric charge of colloidal particles and promote the colloidal particles to sedimentate.

b. To convert the non-hydrated phospholipids to hydrated phospholipids.

c. Alum: flocculant aid. Alum can absorb pigments in oil.

d. To chelate with metal ions and remove them.

e. To promote the colloidal flocculation closer and reduce the oil content of flocs.

3.5 Other factors

(1) Uniformity of oil: Before hydration, the crude oil should be fully stirred so that the colloid can be distributed evenly.

(2) temperature of added water: When hydration, the temperature of adding water should be equal to or slightly higher than the oil temperature.

(3) Added water quality

(4) Operational stability

Generally speaking, technical parameters of the degumming process is determined according to the quality of the oil, and the parameters of different oils in the degumming process are different. If you have interest in refining oil, please contact us with your questions or ideas. We will arrange our professional engineers to customize a suitable oil line which equipped with the corresponding oil refining equipment for you.