High Quality for Food Dryer Machine Price - TQLZ Vibration Cleaner – Fotma

High Quality for Food Dryer Machine Price - TQLZ Vibration Cleaner – Fotma Detail:

Product Description

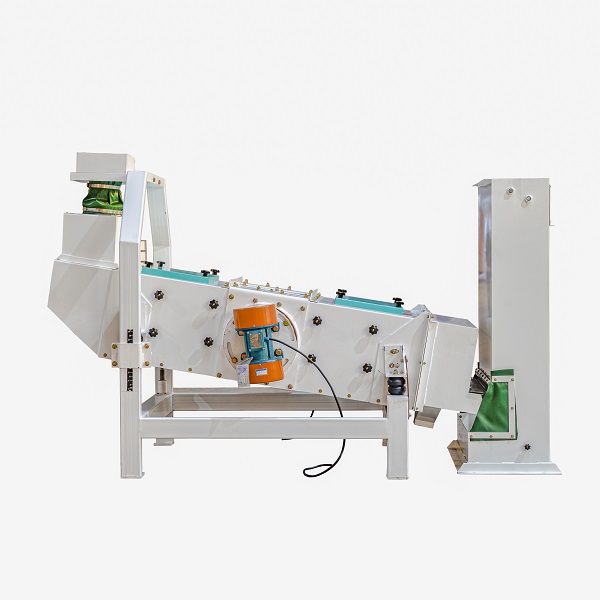

TQLZ Series vibrating cleaner, also called vibrating cleaning sieve, can be widely used in the initial processing of rice, flour, fodder, oil and other food. It is generally erected in paddy cleaning procedure to remove large, small and light impurities. By equipped with different sieves with different meshes, the vibrating cleaner can classify the rice according to its size and then we can get the products with different sizes.

The vibration cleaner has a two-tier screen surface, sealing well. As a result of the vibration motor drive, the size of excitation force, vibration direction and the screen body angle can be adjusted, the cleaning effect for the raw materials containing large miscellaneous is very good, it can also be used for food, chemical industry for particle separation. Different specifications of the screen surface can be used to clean large and small light miscellaneous of wheat, rice, maize, oil-bearing crops, etc.

The vibrating cleaner is characterized by high removing-impurity efficiency, stable performance, smooth operation, low power consumption, low noise, good tightness, easy assembling, disassembling and repair, etc. It also has the advantages of compact construction, high production efficiency, low maintenance requirement, easily removable inspection covers, simple and precise motor alignment.

Features

1. Compact structure, good sealing performance;

2. Smooth operation and stable performance;

3. Low power consumption and low noise;

4. Effect cleaning, high production efficiency;

5. Easy on assembling, disassembling and repair.

Technique Parameter

|

Model |

TQLZ80 |

TQLZ100 |

TQLZ125 |

TQLZ150 |

TQLZ200 |

|

Capacity(t/h) |

5-7 |

6-8 |

8-12 |

10-15 |

15-18 |

|

Power (kW) |

0.38×2 |

0.38×2 |

0.38×2 |

0.55×2 |

0.55×2 |

|

Sieve inclination(°) |

0-12 |

0-12 |

0-12 |

0-12 |

0-12 |

|

Sieve width(mm) |

800 |

1000 |

1250 |

1500 |

2000 |

|

Total weight(kg) |

600 |

750 |

800 |

1125 |

1650 |

Product detail pictures:

Related Product Guide:

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for High Quality for Food Dryer Machine Price - TQLZ Vibration Cleaner – Fotma , The product will supply to all over the world, such as: Bogota, Casablanca, United States, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.