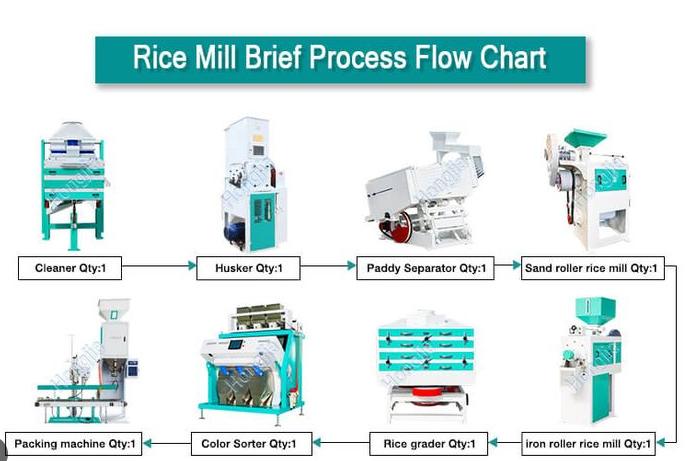

Rice processing mainly includes steps such as threshing, cleaning, grinding, screening, peeling, dehulling, and rice milling. Specifically, the processing procedure is as follows:

1. Threshing: Separate the rice grains from the spikes;

2. Cleaning: Remove straw, pulp, and other impurities;

3. Grain milling: Remove the husks from the cleaned rice to obtain rice grains;

4. Screening: Divide rice into different grades with varying particle sizes;

5. Peeling: Removing the outer skin of rice to obtain brown rice;

6. Embryo removal: After the embryo of brown rice is removed by the embryo removal machine, paste rice is obtained;

7. Grinding rice: After the paste rice is ground by a rice grinder, white rice is obtained.

There are various types and scales of rice processing equipment, but the basic process is similar. The main equipment includes threshers, cleaning machines, grain grinders, screening machines, hullers, dehullers, and rice grinders.

Quality control of rice

The quality control of rice is crucial to the rice milling processing process. The quality of rice is influenced by various factors, such as rice variety, quality, storage, processing technology, grinding technology, and equipment. To control the quality of rice, it is necessary to manage and adjust these factors to ensure that the quality of each batch of rice is uniform and stable.

Common processing issues

In the process of rice processing, there are some common problems such as grain breakage, excessive wear, grain cracks, and color difference. These issues need to be addressed in a timely manner to ensure the quality and yield of rice.

In short, how rice becomes rice is a very important and complex process. Only by adopting correct processing methods and controlling quality can high-quality rice products be obtained.

Post time: Jan-02-2025