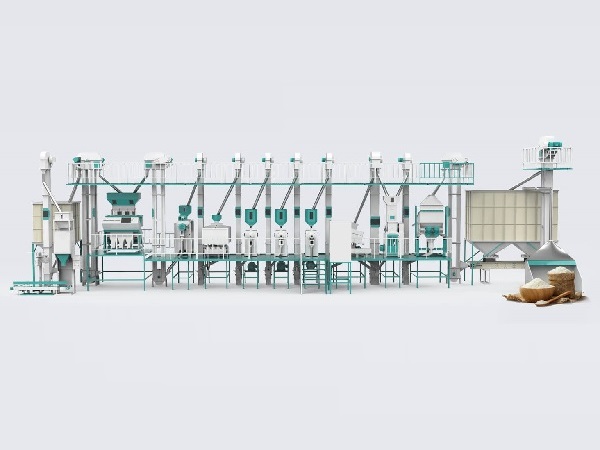

Rice Milling Facility’s Configurations

The rice milling facility comes in various configurations, and the milling components vary in design and performance. “Configuration” refers to how the components are sequenced. The flow diagram below shows a modern commercial mill catering to the higher end market. It has three basic stages:

A. The husking stage,

B. The whitening-polishing stage, and

C. The grading, blending, and packaging stage.

Objective of Commercial Milling

A commercial rice miller will have following objectives:

a. Produce edible rice that appeals to the customer- i.e. rice that is sufficiently milled and free of husks, stones, and other non-grain materials

b. Maximize the total milled rice recovery out of paddy minimize grain breakage.

Simply speaking, the objective of commercial rice milling is to reduce mechanical stresses and heat buildup in the grain, thereby minimizing grain breakage and producing uniformly polished grain.

In modern rice mills, many adjustments (e.g. rubber roll clearance, separator bed inclination, feed rates) are automated for maximum efficiency and ease of operation. The whitener-polishers are provided with gauges that sense the current load on the motor drives which gives an indication of the operating pressure on the grain. This provides a more objective means of setting milling pressures on the grain.

Post time: Mar-17-2023