Oil Seeds Pretreatment: Groundnut Shelling Machine

The main oil seeds shelling equipment

1. Hammer shelling machine (peanut peel).

2. Roll-type shelling machine (castor bean peeling).

3. Disk shelling machine (cottonseed).

4. Knife board shelling machine (cottonseed shelling) (Cottonseed and soybean, peanut broken).

5. Centrifugal shelling machine (sunflower seeds, tung oil seed, camellia seed, walnut and other shelling).

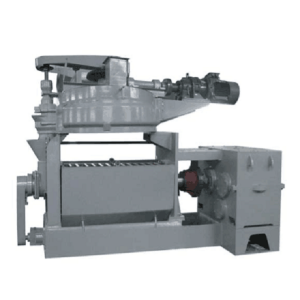

Groundnut Shelling Machine

Peanut or groundnut is one of the important oil crops in the world, groundnut kernel is often used to make cooking oil. Peanut huller is used to shell peanuts, it can shell peanut completely, separate shells and kernels with high-efficiency and almost without damage to the kernel. The shelling rate can be ≥95%, the breaking rate is≤5%. While peanut kernels are used for food or the raw material for oil mill, the shell could be used to make wood pellets or charcoal briquettes for fuel.

FOTMA groundnut shelling machine is produced according to the national standards strictly. It consists of rasp bar, stake, intaglio, fan, gravity separator and second bucket, etc. The whole groundnut shelling machine frame is made of high-quality steel and the shelling chamber is made of stainless steel. Our groundnut shelling machine has compact structure, easy operation, high efficiency, low energy consumption and reliable performance. We export peanut shelling machine or groundnut huller on cheap price.

How does the groundnut shelling machine work?

After starting, the shells of peanuts are shelled by the rolling force between the rotating rasp bar and the fixed intaglio, and then shells and kernels fall through the grid mesh down to the air duct, and the fan blows shells out. The kernels and the unshelled small peanuts fall into the gravity separator. The separated kernels are sent upward to the outlet and the separated unshelled small peanuts are sent downwards to the elevator, and the elevator sends the unshelled peanut to the fine grid mesh to be shelled again until the whole batch of peanuts are all shelled.

Groundnut Shelling Machine Techinal Data

|

6BK Series Peanut Huller |

||||

| Model |

6BK-400B |

6BK-800C |

6BK-1500C |

6BK-3000C |

| Capacity(kg/hr) |

400 |

800 |

1500 |

3000 |

| Power(kw) |

2.2 |

4 |

5.5-7.5 |

11 |

| Shelling rate |

≥95% |

≥95% |

≥95% |

≥95% |

| Breaking rate |

≤5% |

≤5% |

≤5% |

≤5% |

| Losing rate |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

| Cleaning rate |

≥95.5% |

≥95.5% |

≥95.5% |

≥95.5% |

| Weigh t(kg) |

137 |

385 |

775 |

960 |

| Overal dimensions (L×W×H) (mm) |

1200×660×1240mm |

1520×1060×1660mm |

1960×1250×2170mm |

2150×1560×2250mm |

|

6BH Peanut Shelling Machine |

|||||

| Model |

6BH-1600 |

6BH-3500 |

6BH-4000 |

6BH-4500A |

6BH-4500B |

| Capacity(kg/h) |

1600 |

3500 |

4000 |

4500 |

4500 |

| Shelling rate |

≥98% |

≥98% |

≥98% |

≥98% |

≥98% |

| Broken rate |

≤3.5% |

≤3.8% |

≤3% |

≤3.8% |

≤3% |

| Loss rate |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

| Damage rate |

≤2.8% |

≤3% |

≤2.8% |

≤3% |

≤2.8% |

| Impurity rate |

≤2% |

≤2% |

≤2% |

≤2% |

≤2% |

| Matched power(kw) |

5.5kw+4kw |

7.5kw+7.5kw |

11kw+11kw+4kw |

7.5kw+7.5kw+3kw |

7.5kw+7.5kw+3kw |

| Operators |

2~3 |

2~4 |

2~4 |

2~4 |

2~3 |

| Weight(kg) |

760 |

1100 |

1510 |

1160 |

1510 |

| Overal dimensions (L×W×H) (mm) |

2530×1100×2790 |

3010×1360×2820 |

2990×1600×3290 |

3010×1360×2820 |

3130×1550×3420 |

|

6BHZF Series Peanut Sheller |

|||||

| Model |

6BHZF-3500 |

6BHZF-4500 |

6BHZF-4500B |

6BHZF-4500D |

6BHZF-6000 |

| Capacity(kg/h) |

≥3500 |

≥4500 |

≥4500 |

≥4500 |

≥6000 |

| Shelling rate |

≥98% |

≥98% |

≥98% |

≥98% |

≥98% |

| The peanut-containing rate in kernels |

≤0.6% |

0.60% |

≤0.6% |

≤0.6% |

≤0.6% |

| The trash-containing rate in kernels |

≤0.4% |

≤0.4% |

≤0.4% |

≤0.4% |

≤0.4% |

| Breakage rate |

≤4.0% |

≤4.0% |

≤3.0% |

≤3.0% |

≤3.0% |

| Damage rate |

≤3.0% |

≤3.0% |

≤2.8% |

≤2.8% |

≤2.8% |

| Loss rate |

≤0.7% |

≤0.7% |

≤0.5% |

≤0.5% |

≤0.5% |

| Matched power(kw) |

7.5kw+7.5kw; |

4kw +5.5kw; |

4kw +5.5kw; 11kw+4kw+7.5kw |

4kw +5.5kw; 11kw+4kw+11kw |

5.5kw +5.5kw; 15kw+5.5kw+15kw |

| Operators |

3~4 |

2~4 |

2~4 |

2~4 |

2~4 |

| Weight(kg) |

1529 |

1640 |

1990 |

2090 |

2760 |

|

Overal dimensions |

2850×4200×2820 |

3010×4350×2940 |

3200×5000×3430 |

3100×5050×3400 |

3750×4500×3530 |