Renewable Design for Mini Rice Mill Plant Cost - TQLZ Vibration Cleaner – Fotma

Renewable Design for Mini Rice Mill Plant Cost - TQLZ Vibration Cleaner – Fotma Detail:

Product Description

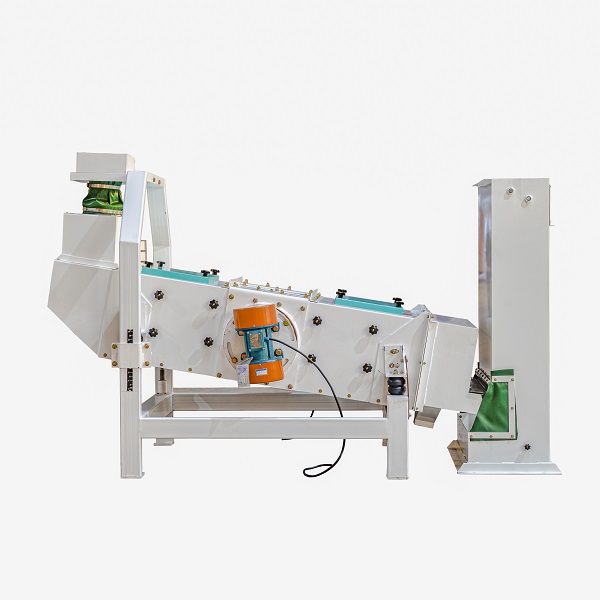

TQLZ Series vibrating cleaner, also called vibrating cleaning sieve, can be widely used in the initial processing of rice, flour, fodder, oil and other food. It is generally erected in paddy cleaning procedure to remove large, small and light impurities. By equipped with different sieves with different meshes, the vibrating cleaner can classify the rice according to its size and then we can get the products with different sizes.

The vibration cleaner has a two-tier screen surface, sealing well. As a result of the vibration motor drive, the size of excitation force, vibration direction and the screen body angle can be adjusted, the cleaning effect for the raw materials containing large miscellaneous is very good, it can also be used for food, chemical industry for particle separation. Different specifications of the screen surface can be used to clean large and small light miscellaneous of wheat, rice, maize, oil-bearing crops, etc.

The vibrating cleaner is characterized by high removing-impurity efficiency, stable performance, smooth operation, low power consumption, low noise, good tightness, easy assembling, disassembling and repair, etc. It also has the advantages of compact construction, high production efficiency, low maintenance requirement, easily removable inspection covers, simple and precise motor alignment.

Features

1. Compact structure, good sealing performance;

2. Smooth operation and stable performance;

3. Low power consumption and low noise;

4. Effect cleaning, high production efficiency;

5. Easy on assembling, disassembling and repair.

Technique Parameter

|

Model |

TQLZ80 |

TQLZ100 |

TQLZ125 |

TQLZ150 |

TQLZ200 |

|

Capacity(t/h) |

5-7 |

6-8 |

8-12 |

10-15 |

15-18 |

|

Power (kW) |

0.38×2 |

0.38×2 |

0.38×2 |

0.55×2 |

0.55×2 |

|

Sieve inclination(°) |

0-12 |

0-12 |

0-12 |

0-12 |

0-12 |

|

Sieve width(mm) |

800 |

1000 |

1250 |

1500 |

2000 |

|

Total weight(kg) |

600 |

750 |

800 |

1125 |

1650 |

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for Renewable Design for Mini Rice Mill Plant Cost - TQLZ Vibration Cleaner – Fotma , The product will supply to all over the world, such as: Angola, Slovakia, Egypt, We aim to become the modern enterprise with the commercial ideal of "Sincerity and confidence" and with the aim of "Offering customers the most sincere services and best quality products". We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.